A well-known global chemical company: building a digital supply chain

Headquartered in Europe, the company is a worldwide multinational group in the field of applied chemistry, with operations in Europe, North America, Asia-Pacific and Latin America, manufacturing and trading more than 10,000 products for civil and industrial use in nearly 75 countries, and employing more than 50,000 people worldwide.

Through a globally balanced and diversified portfolio of businesses, outstanding innovations and advanced technologies, the company has established a leading position in its two business segments, Industrial and Consumer. As an example of sustainable corporate development, the company ranks high in many international indices and rankings.◆ Need to effectively prevent counterfeiting, safeguard product quality and reduce the risk of brand credibility damage

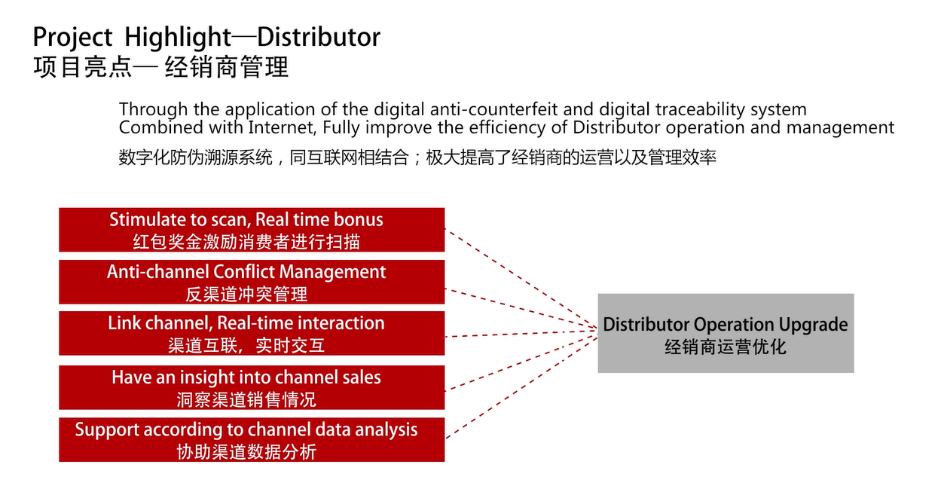

◆ Improve operational efficiency, scientifically manage dealers, avoid cross-regional sales or stockpiling, and enhance channel transparency

◆ By digitally upgrading the existing supply chain and utilizing the underlying digital capabilities to empower enterprises, eliminating data silos and enhancing the ability of comprehensive data integration

➢Digitized product identity ID to create a digital file for tracking and tracing

Tracking and tracing of products is achieved by assigning a unique digital identity ID to each product. Technologies such as QR codes, bar codes or RFID are used on product packaging, and consumers can scan or enter the code to obtain detailed information about the product, including the date of production, location of production, and supply chain information.

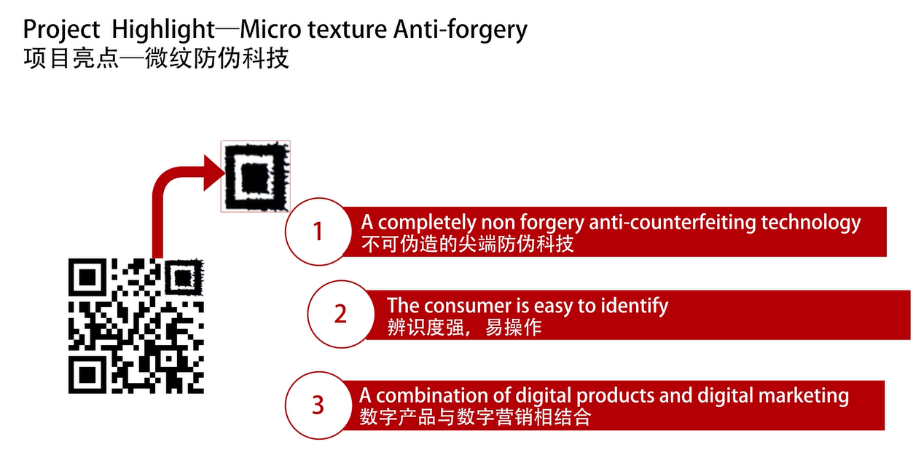

➢ Anti-counterfeiting black technology: micro-texture code®

➢ Intelligent Warehousing WMS & Logistics

✔ Supply Chain Planning: Based on historical data through algorithms to automatically generate procurement, production, sales and other plans and adjust them according to the actual situation.

✔ Inventory Management: Real-time monitoring of global inventory, automatic replenishment and inventory adjustment to reduce inventory costs.

✔ Procurement management: Realize information sharing with procurement departments to improve procurement efficiency.

✔ Logistics management: monitoring the whole logistics process, optimizing the path and improving the efficiency of logistics.

➢ Anti-flouting Audit

✔ Through the establishment of a digital archive system, information on product production, transportation and sales is recorded. The source of raw materials, records of the production process, quality test results, etc. can be accessed through traceability when necessary to ensure product quality and safety.

✔ Protect your company's intellectual property and brand through the random, unique and non-replicable Microtexture Code®

✔ Realize the management of raw material warehouse and finished product warehouse, with the help of one-dimensional code, two-dimensional code and RFID related technology, realize the information management of warehousing; WMS intelligent guidance operation, greatly improve the efficiency of warehousing management.

✔ Effective management of wide-area distribution channels, monitoring the flow of products, effective prevention of tampering phenomenon, to solve the contradiction between sales and production disconnect as well as the problem of unbalanced inventory in various regions; enterprise managers can timely grasp the business processes, data, problems in all aspects of logistics management, so as to scientifically control the overall logistics and sales operations.