LINKWIN Case Sharing

Company profile

This company is one of the largest orthopedic and medical technology companies in the world, headquartered in the United States, with 14 production, research and development, and sales branches worldwide, and more than 16000 employees.

Due to its excellent performance, the company has been named one of the Fortune 500 companies and one of the top 50 healthcare companies in the United States by renowned American magazines such as Fortune and Business Week.

The challenges and project requirements faced by digital transformation

➢ The challenges faced by digital transformation

With the comprehensive upgrade of software and hardware, it is necessary to promote the significant improvement of the three core capabilities of control system, production manufacturing, and testing efficiency, and build the core competitiveness of manufacturing enterprises in the digital era.

· Potential issues with product labeling: If manual labeling is used throughout the packaging process, there may be situations where the product is labeled incorrectly, the label has no content, the label content is missing, the instruction manual does not match the product, and sterilization labels are omitted.

· Accuracy of ERP related information: The detection data of the entire production line will be linked to the ERP system to ensure consistency between products and order requirements.

➢ Project requirements

In summary, industrial visual technology is used to inspect the instruction manual and all aspects of the product to ensure that it meets the order requirements and quality standards.

LINKVISION Visual Inspection Solution

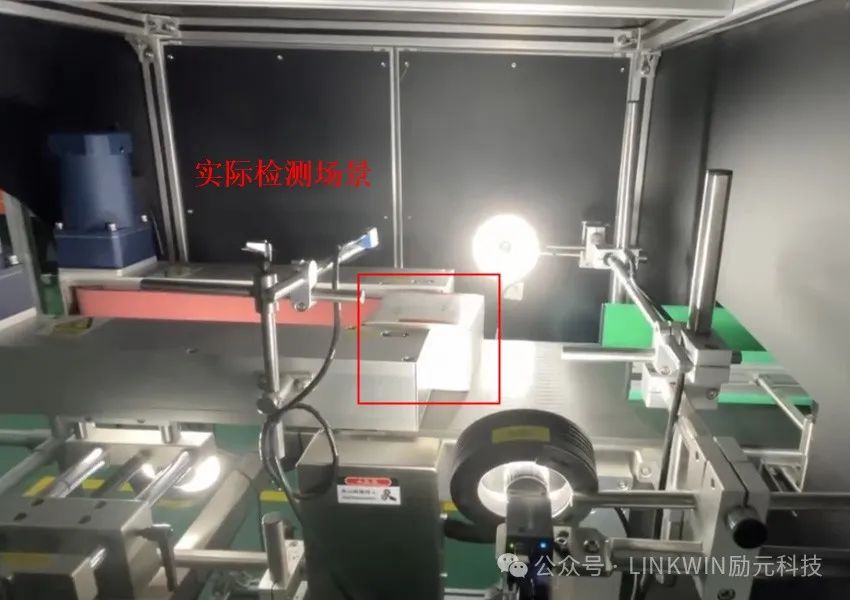

Actual detection scenario

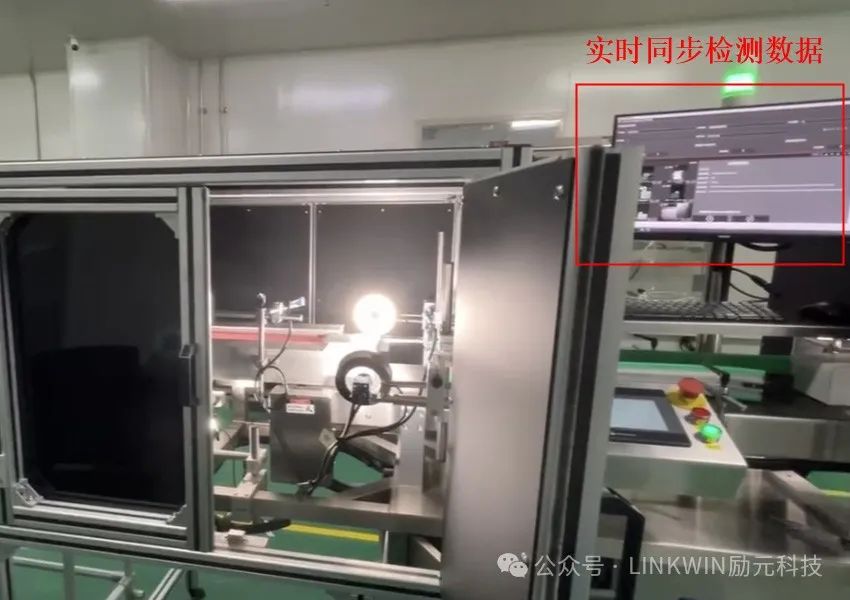

Real time synchronous detection data

·By adding a detection conveyor belt, the product is automatically transported, and visual cameras are used to identify and detect the detection points

·Compare product content using IPC program (such as whether the label and instruction manual match the product of this production batch)

The testing content includes:

·Label certificate information (product batch number, name, code);

·Instructions (completeness of document number, version number, registration certificate number);

·The accuracy of the book's content;

·The accuracy of the placement of the label certificate of conformity;

·Integrity and consistency of pasting sterilization labels;

·The correctness of pasting labels on the inner packaging;

·Label barcode recognition detects the integrity of its digits;

·Check the consistency between the products on the production line and the order/batch number;

·Check the consistency of all labels and whether they match the order requirements

Project application effect

By using industrial vision for product inspection, the following application effects can be achieved:

·Accuracy and consistency of testing content: Ensure that product quality meets standards.

·Real time monitoring of product production process: timely detection and resolution of production problems, improving production efficiency.

·Reduce the impact of human factors on product testing: improve the stability and reliability of production lines.

·Assist enterprises in achieving automatic inspection and quality control of product packaging: improve packaging efficiency and accuracy.

·Sedimentation of data assets: achieving optimization and improvement of the production process.

The application of industrial visual technology has made the enterprise a fully covered enterprise in detection automation. LINKWIN Liyuan Technology has become a partner in its digital transformation, and will continue to provide comprehensive digital transformation services in the future to help the enterprise operate excellently and develop with high quality.